By now, most people are probably familiar with the concept of 3D printing. Even from 10 years ago, the technology has come quite a long way, and is much more accessible. It’s even changing the world of healthcare by providing new, exciting options for treatments and surgeries. Virtually anything can be made from a 3D printer, and yes, that even includes realistic-looking dental implants.

Now, we’re not saying that missing tooth implants are going to be crafted from the plastic-y filament that most people associate with 3D printing. You still get your durable titanium dental implants and zirconia implants for lost teeth. The fit is way more precise, and there’s a decreased risk of complications post-operation. Dental implant surgeons all around the world are championing this innovative technology. So how does it work?

3D Printing Used in the Planning Stage

Before your surgeon who installs replacement teeth actually gets in your mouth to pop in a new faux tooth that looks like the real deal, they have to take multiple steps back and plan. The planning stage is vital for creating quality dental implants that will last a long time. This involves looking at a patient’s particular mouth anatomy and creating a custom implant for missing teeth that fits well in their specific mouth. Without the planning stage, dental surgeons who help with tooth implants would basically be winging it and hoping for the best.

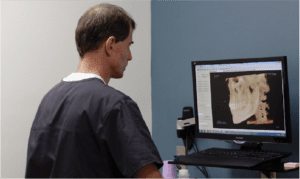

3D printing technology allows for diagnostic accuracy that far surpasses what was previously achievable. Dental implant surgeons normally take CT scans of their patients, which provide detailed 3D images of the mouth structure. 3D printing allows your tooth implant dentist to take that a step further and print out a physical model of your mouth. Pretty cool, right? The extreme level of detail in the physical model gives your surgeon a precise representation of everything happening in your mouth. Bone density, nerve pathways, and existing dental structures—it’s all there.

The 3D printed model is used to:

- Plan the placement of well-fitting dental implants – the model allows the surgeon to scope out the best positions for implants while avoiding structures like the sinuses and nerves.

- Assess bone quality – a patient’s jawbone needs to be in good order to receive a metal tooth implant. Seeing a physical model helps determine the potential need for dental bone grafting prior to the implant.

- Practice surgical procedures – think of it like your tooth replacement doctor practicing before a big presentation. They’re putting in the extra work beforehand so they can absolutely nail it when the big day rolls around. Having a model to practice on improves precision and greatly reduces the risk of complications.

3D Printing in Dental Implant Creation

3D printing has also changed the way tooth replacement implants are made. By utilizing the technology, it’s possible to create fully customized dental implants that will last for decades. Each implant is created with the patient’s full mouth anatomy in mind. With 3D printing, the oral surgeon performing the tooth replacement procedure is able to craft an implant with complex geometries that exactly matches the bone structure of the patient. It’s a level of precision that you just can’t get to with the more traditional manufacturing processes.

Because they’re totally custom, the 3D printed dental implant for missing teeth fits way snugger with the jawbone. It increases stability tenfold and decreases the possible risk of the titanium tooth replacement moving or becoming loose over time. It even enhances osseointegration, the process where the titanium post integrates or fuses with the jawbone. Implants crafted using 3D printing technology are able to have specialized surface textures that actually mimic the natural bone structure. Dental implant surgeons, with the help of 3D printing, construct a much more favorable environment for bone cells to latch onto the surface during osseointegration. The level of detail in the technology is almost mind-blowing and goes an incredibly long way in ensuring patients have successful outcomes.

Like traditional implants, 3D printers can make use of both titanium and zirconia materials when producing a custom-made implant. Both materials are great, viable options for dental implants that can last decades, and your tooth implant dental doctor will discuss the best choices with you.

The Future of 3D Printing in Tooth Replacements

So, it’s probably pretty clear by now that 3D printing has more or less totally transformed the way well-made dental implants for missing teeth are created. As technology is constantly changing and shifting, new breakthroughs are discovered. What’s next in the field of dental implants? 4D printing is actually one of the latest emerging technologies that hasn’t fully caught on yet and is still in the early stages. 4D introduces the element of time into the mix, and it can make some spectacular results. Self-adjusting implants that change in size or shape to best fit the current patient mouth structure sounds like something out of a sci-fi film, but it’s completely possible with 4D printing technology.

3D printing completely changes the world of dental implant treatment, and it offers patients more precise and personalized outcomes with a high success rate. And maybe if you’re lucky, your tooth implant dental surgeon will let you keep the physical model of your mouth.